| High Quality Thermoplastic Compressor Valve Parts

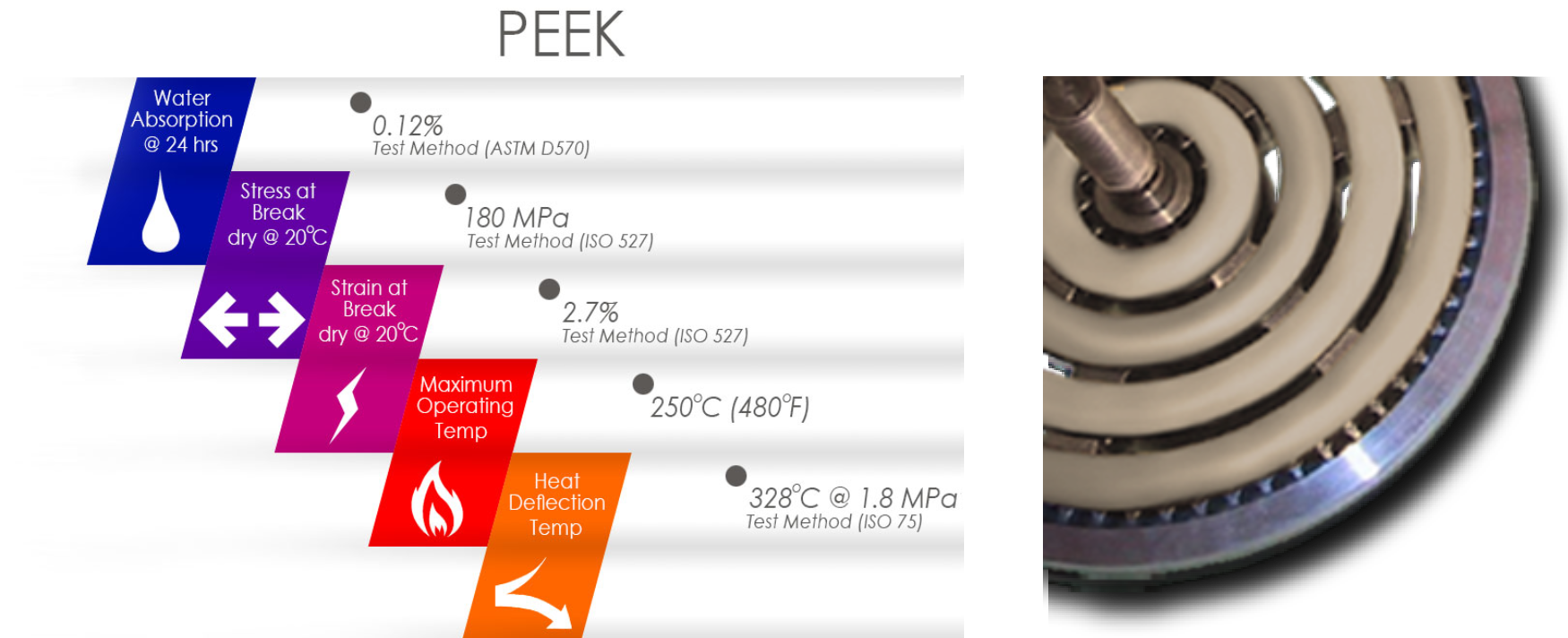

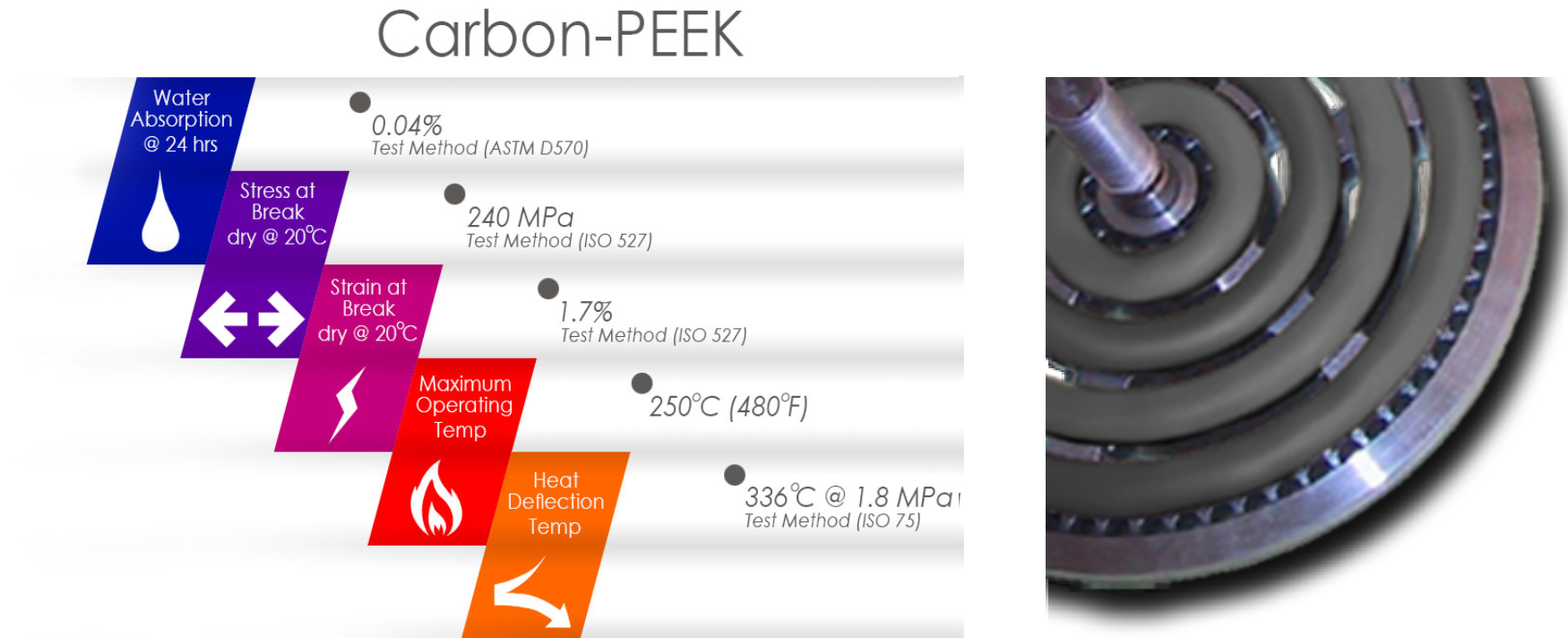

KBDME's Thermoplastic compressor valve plates and valve rings excel in the market by incorporating PEEK and Carbon PEEK materials. These advanced materials offer exceptional durability, chemical resistance, and high-temperature stability. The combination of precision engineering and the use of PEEK & Carbon PEEK ensures superior performance, making KBDME the industry leader for those prioritizing reliability and efficiency in thermoplastic compressor components.

| All Products are Available in Nylon, MT, Peek, Carbon-Peek and X-Type

| Product Type

PORTED PLATES

RADIUS RINGS

POPPETS

BUTTONS AND NUBS

| Product Type

| Resource Data Sheets

| Our Process & Capabilities

THE RIGHT THERMOPLASTIC

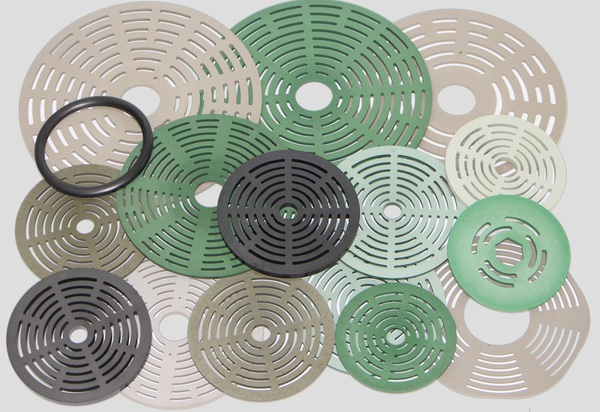

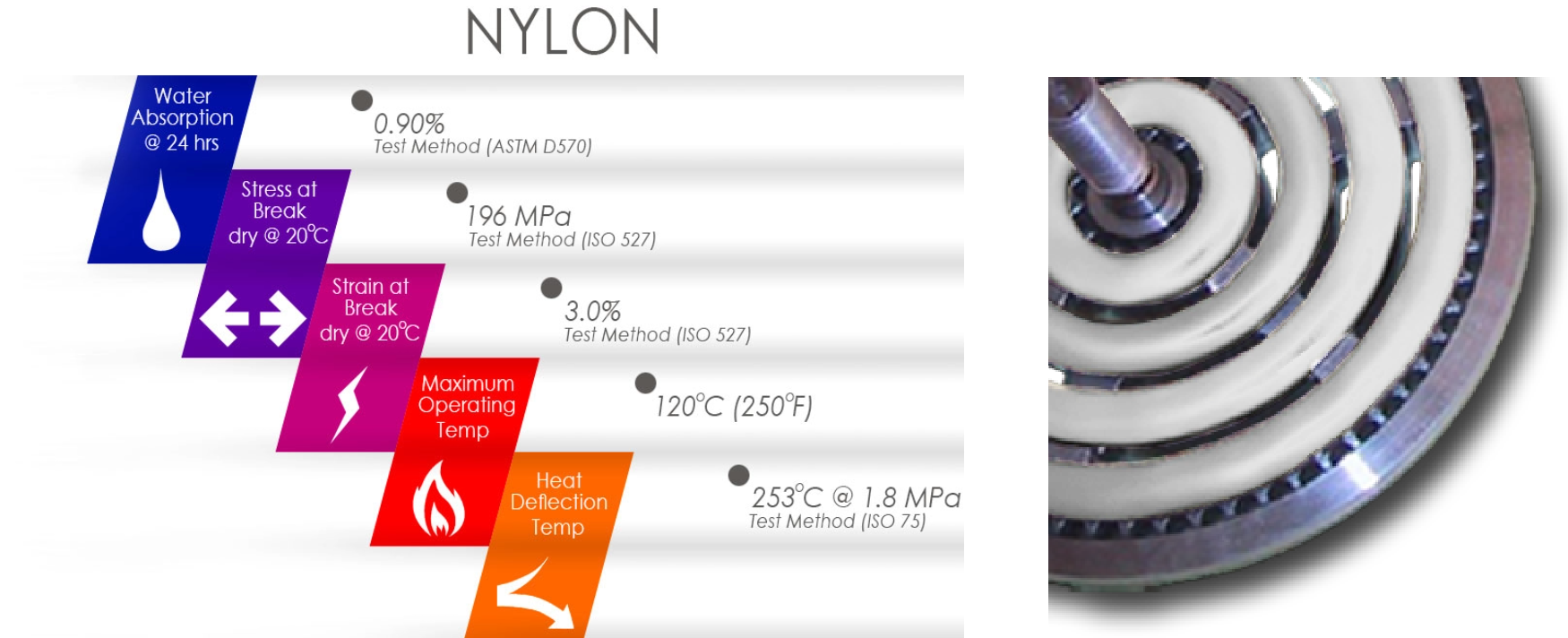

Choosing the right thermoplastic, such as Nylon, PEEK, MT, and carbon-filled PEEK, for compressor valve plates and rings is crucial for optimal performance.

Nylon offers good strength, abrasion resistance, and cost-effectiveness. PEEK provides excellent chemical resistance, high-temperature stability, and mechanical strength, enhancing the durability of compressor components. MT, known for its high-temperature resistance and dimensional stability, is suitable for demanding environments. Carbon-filled PEEK combines the advantages of PEEK with enhanced strength and conductivity.

The selection depends on specific application requirements, including temperature, chemical exposure, and mechanical stress, ensuring reliable and efficient compressor operations.

STATE-OF-THE-ART PROCESS

Our company is proud to be at the forefront of the manufacturing industry when it comes to compressor Parts. With our state-of-the-art process, we ensure that the Compressor parts we produce are of the highest quality, designed to meet the rigorous demands of various industries.

Our manufacturing process incorporates the latest technologies and techniques from the selection of the finest materials to the precision engineering of each part, we pay meticulous attention to detail to ensure optimal performance.

At every step of the manufacturing process, our skilled and experienced team monitors and tests the parts to ensure their adherence to strict quality standards. We believe that it is this commitment to quality that sets us apart from our competitors.

In addition to our dedication to quality, we also prioritize innovation and continuous improvement. We strive to stay ahead of the curve by investing in research and development.

OEM STANDARDS

When it comes to compressor parts, we ensure that our products are manufactured according to Original Equipment Manufacturer (OEM) standards. We understand the importance of using original and high-quality parts to maintain the performance and reliability of compressors.

By adhering to OEM standards, we guarantee that our compressor parts are designed to fit seamlessly and function efficiently within different compressor systems. We prioritize precision engineering and use top-grade materials to meet the stringent specifications set by OEM manufacturers.

Our commitment to OEM standards extends to rigorous quality control measures throughout the manufacturing process. We conduct thorough inspections and tests to ensure that our parts meet the exact specifications and standards set by the OEM manufacturer. This allows us to eliminate any potential defects and ensure that our customers receive parts that are reliable and durable.

Our Aim to provide our customers with reliable, long-lasting, and compatible parts that ultimately contribute to the smooth operation of their compressor systems.